|

By Kyle Warner

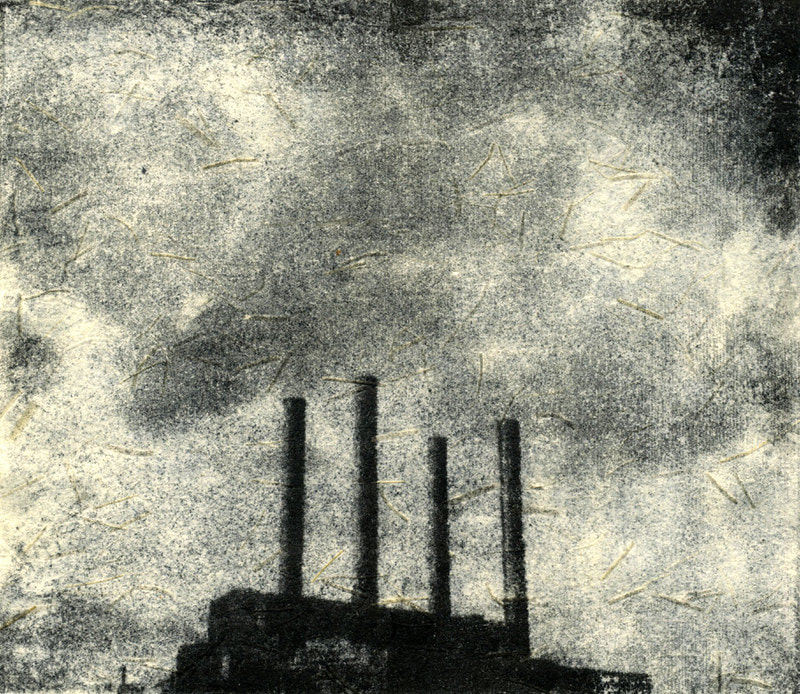

The Intergovernmental Panel on Climate Change’s (IPCC) recent report makes it clear that if we are to avoid the worst impacts of global warming, we need to make drastic industrial-scale changes now. The report not only confirms the need for a reduction in greenhouse gas emissions, but also highlights the importance of pursuing carbon capture and storage technologies to undo the damage that has already been done. In order to avoid an increase of global temperatures to 1.5 degrees Celsius above pre-industrial levels, the benchmark limit set by the Paris Agreement, going carbon neutral will not be enough; carbon negative is the new mandatory. Fortunately, there are wide-ranging applications for capturing and using carbon, and with the budget bill passed by President Trump earlier this year that provides incentives for carbon capture, the development of these technologies is occurring at a rapid pace. In its most general form, carbon capture and storage refers to the process of removing waste carbon dioxide (CO2) from point sources and either storing or utilizing it in a way that prevents it from entering the atmosphere. The most logical application for carbon capture technology is use by the greatest carbon emitters—fossil fuel power plants. In these cases, there are three approaches that can be taken: post-combustion capture, pre-combustion capture, and oxy-fuel combustion. For pre-existing power plants, post-combustion carbon capture is the most viable option because it can be easily implemented on most smokestacks. This process separates CO2 from “flue gases,” which are released during the combustion of fossil fuels. A filter-like “scrubber” that acts as a solvent for CO2 is fitted to the smokestack, and once the scrubber becomes saturated it can be heated to release water vapor and leave behind concentrated liquid CO2. Post-combustion carbon capture effectively prevents 80-90% of a plant’s carbon emissions from entering the atmosphere, but there is still a lack of incentive for companies to pursue this technology. It costs roughly $60 per metric ton to capture and store carbon, whereas the budget bill only allocates $50 per metric ton. There are currently only seventeen large-scale post-combustion carbon capture plants in the world, which absorb less than 1% of global emissions, but rapid growth should be anticipated as the technology becomes cheaper and increasing pressure is placed on power plants by environmental lobbyists and government officials. For future power plants, carbon capture will be best achieved through pre-combustion capture and oxy-fuel combustion. During pre-combustion carbon capture, the fuel source is heated in pure oxygen prior to combustion, resulting in a mixture of carbon monoxide and hydrogen, which is then treated with a catalytic converter to produce CO2 and more hydrogen. Subsequently, a chemical compound called an amine is introduced that binds to the CO2, and these newly-formed molecules sink to the bottom of the mixture. The CO2 can then be easily separated from the fuel and the excess hydrogen can be used in alternative energy production or as a future fuel source that can, for example, power cars and heat homes. Although cheaper than post-combustion carbon capture, pre-combustion capture is not applicable to older pulverized coal power plants which unfortunately make up the majority of the current fossil fuel energy market. However, pre-combustion capture remains an efficient, cost-effective method of CO2 removal and should be a significant consideration in all future power plant designs. With oxy-fuel carbon capture, the fossil fuel is combusted in air heavily diluted with oxygen. This unique form of combustion releases flue gas consisting of high concentrations of CO2 and water vapor, which can then be easily separated out by cooling and compressing the gas. While this is effective at preventing 90% of the CO2 released from entering the atmosphere, the cost of the oxygen required for combustion is still too high for large-scale applications. After the CO2 has been captured, it needs to be either transported to storage or reallocated for commercial use. Methods of transport follow the same traditional means as oil or natural gas (road tankers, ships, and pipelines), but each project comes with its own considerations, and an appropriate method of transport for CO2 should be chosen subject to planning and health and safety regulations. Large commercial networks of reliable CO2 pipelines have been in place for over thirty years, but there remains significant potential for development of local and regional pipeline infrastructure to lower the cost of carbon capture altogether. Once transported, CO2 is most efficiently stored in porous geological formations several kilometers beneath the Earth’s surface. Examples of acceptable sites include old oil and gas fields and deep saline aquifers. These sites subject the CO2 to high pressures and temperatures that allow it to remain in the liquid phase and prevent ease of escape. Once injected into the ground, the CO2 rises until it becomes trapped under an impermeable layer of rock. Over time, this CO2 will either dissolve into the surrounding salt water and sink to the bottom of the storage site, or it will chemically and irreversibly bind to the surrounding rock. Although most of the CO2 captured today is stored underground, there are several promising applications for commercial use as well. One of the most encouraging commercial applications for carbon capture is the use of carbon fiber in architecture and building materials. CO2 captured from the air can be used to directly produce carbon fiber which is great for structural support as it is lighter than steel, five times stronger, and twice as stiff. As of now, carbon fiber production from captured CO2 has only been used in small-scale projects and requires more research in order to decrease costs enough for large-scale implementation. This is a potentially massive future market, however, that could significantly increase incentives for pulling carbon from the atmosphere and should thus demand significant investment. Other promising applications for usage of captured carbon include the sale of the liquid CO2 required for beverage carbonation to soda companies, the production of carbon neutral synthetic fuels identical to gasoline, the use of degradable plastics made from CO2, and the incorporation of CO2 into desalination plants to stabilize pH levels. As the IPCC report states, we must act now to stabilize the climate and prevent catastrophic weather events, sea level rise, and ocean acidification. It is vital that carbon capture becomes more widespread and applications such as these continue to be developed if we are to commence carbon negativity. We have all of the capabilities necessary to achieve this goal, but if we do not act urgently, we will reap the consequences for centuries to come.

0 Comments

Leave a Reply. |

Categories

All

Archives

April 2024

|